A capacitor (initially known as a condenser) is a latent two-terminal electrical part used to incidentally store electrical vitality in an electric field. The types of down to earth capacitors change broadly, yet most contain no less than two electrical conduits (plates) isolated by a dielectric. The conveyors can be thin movies, thwarts or sintered dots of metal or conductive electrolyte, and so forth. The nonconducting dielectric acts to expand the capacitor's charge limit. Materials normally utilized as dielectrics incorporate glass, clay, plastic film, paper, mica, and oxide layers. Capacitors are broadly utilized as parts of electrical circuits in numerous basic electrical gadgets. Not at all like a resistor, a perfect capacitor does not disseminate vitality. Rather, a capacitor stores vitality as an electrostatic field between its plates.

At the point when there is a potential distinction over the conduits (e.g., when a capacitor is appended over a battery), an electric fielddevelops over the dielectric, bringing on positive charge +Q to gather on one plate and negative charge −Q to gather on the other plate. In the event that a battery has been appended to a capacitor for an adequate measure of time, no current can move through the capacitor. Nonetheless, if a period shifting voltage is connected over the leads of the capacitor, a removal current can stream.

A perfect capacitor is described by a solitary steady esteem, its capacitance. Capacitance is characterized as the proportion of the electric charge Q on every conduit to the potential distinction V between them. The SI unit of capacitance is the farad (F), which is equivalent to one coulomb for every volt (1 C/V). Commonplace capacitance values extend from around 1 pF (10−12 F) to around 1 mF (10−3 F).

The bigger the surface territory of the "plates" (conductors) and the smaller the hole between them, the more noteworthy the capacitance is. By and by, the dielectric between the plates passes a little measure of spillage current furthermore has an electric field quality cutoff, known as the breakdown voltage. The conductors and leads present an undesired inductance and resistance.

Capacitors are generally utilized as a part of electronic circuits for blocking direct present while permitting exchanging current to pass. In simple channel systems, they smooth the yield of force supplies. In resounding circuits they tune radios to specific frequencies. In electric power transmission frameworks, they settle voltage and power flow.[1]

In October 1745, Ewald Georg von Kleist of Pomerania, Germany, found that charge could be put away by interfacing a high-voltage electrostatic generator by a wire to a volume of water in a hand-held glass jar.[2] Von Kleist's hand and the water went about as transmitters, and the container as a dielectric (despite the fact that subtle elements of the system were erroneously recognized at the time). Von Kleist found that touching the wire brought about a capable start, a great deal more excruciating than that acquired from an electrostatic machine. The next year, the Dutch physicist Pieter van Musschenbroekinvented a comparable capacitor, which was named the Leyden shake, after the University of Leiden where he worked.[3] He likewise was inspired by the force of the stun he got, thinking of, "I would not take a second stun for the kingdom of France."[4]

Daniel Gralath was the first to consolidate a few containers in parallel into a "battery" to expand the charge stockpiling limit. Benjamin Franklininvestigated the Leyden container and reached the conclusion that the charge was put away on the glass, not in the water as others had accepted. He likewise received the expression "battery",[5][6] (meaning the expanding of force with a column of comparable units as in a battery of gun), thusly connected to bunches of electrochemical cells.[7] Leyden jugs were later made by covering within and outside of containers with metal thwart, leaving a space at the mouth to counteract arcing between the foils.[citation needed] The most punctual unit of capacitance was the jug, identical to around 1.11 nanofarads.[8]

Leyden containers or all the more capable gadgets utilizing level glass plates rotating with thwart transmitters were utilized only up until around 1900, when the development of remote (radio) made an interest for standard capacitors, and the consistent move to higher frequencies required capacitors with lower inductance. More minimal development techniques started to be utilized, for example, an adaptable dielectric sheet (like oiled paper) sandwiched between sheets of metal thwart, rolled or collapsed into a little bundle.

Early capacitors were otherwise called condensers, a term that is still every so often utilized today, especially in high power applications, as car frameworks. The term was initially utilized for this reason by Alessandro Volta in 1782, with reference to the gadget's capacity to store a higher thickness of electric charge than an ordinary separated conductor.[9]

Since the start of the investigation of power non conductive materials like glass, porcelain, paper and mica have been utilized as covers. These materials a few decades later were additionally appropriate for further use as the dielectric for the principal capacitors. Paper capacitors made by sandwiching a portion of impregnated paper between pieces of metal, and rolling the outcome into a barrel were ordinarily utilized as a part of the late 19century; their make began in 1876,[10] and they were utilized from the mid twentieth century as decoupling capacitors in media communications (communication).

Porcelain was utilized as a part of the primary artistic capacitors. In the early years of Marconi`s remote transmitting mechanical assembly porcelain capacitors were utilized for high voltage and high recurrence application in the transmitters. On the beneficiary side littler mica capacitors were utilized for resounding circuits. Mica dielectric capacitors were developed in 1909 by William Dubilier. Preceding World War II, mica was the most widely recognized dielectric for capacitors in the United States.[10]

Charles Pollak (conceived Karol Pollak), the creator of the main electrolytic capacitors, discovered that the oxide layer on an aluminum anode stayed stable in an impartial or basic electrolyte, notwithstanding when the power was turned off. In 1896 he recorded a patent for an "Electric fluid capacitor with aluminum anodes." Solid electrolyte tantalum capacitors were designed by Bell Laboratories in the mid 1950s as a scaled down and more dependable low-voltage bolster capacitor to supplement their recently developed transistor.

With the improvement of plastic materials by natural physicists amid the Second World War, the capacitor business started to supplant paper with more slender polymer movies. One early advancement in film capacitors was portrayed in British Patent 587,953 in 1944.[10]

To wrap things up the electric twofold layer capacitor (now Supercapacitors) were created. In 1957 H. Becker built up a "Low voltage electrolytic capacitor with permeable carbon electrodes".[10][11][12] He trusted that the vitality was put away as a charge in the carbon pores utilized as a part of his capacitor as in the pores of the carved foils of electrolytic capacitors. Since the twofold layer instrument was not known by him at the time, he wrote in the patent: "It is not known precisely what is occurring in the segment on the off chance that it is utilized for vitality stockpiling, however it prompts to a to a great degree high limit

Showing posts with label Technology. Show all posts

Showing posts with label Technology. Show all posts

Friday, November 4, 2016

Regulator

A voltage controller is intended to consequently keep up a consistent voltage level. A voltage controller might be a straightforward "encourage forward" outline or may incorporate negative criticism control circles. It might utilize an electromechanical instrument, or electronic segments. Contingent upon the plan, it might be utilized to direct at least one AC or DC voltages.

Electronic voltage controllers are found in gadgets, for example, PC control supplies where they balance out the DC voltages utilized by the processor and different components. In vehicle alternators and focal power station generator plants, voltage controllers control the yield of the plant. In an electric power circulation framework, voltage controllers might be introduced at a substation or along conveyance lines so that all clients get relentless voltage free of how much power is drawn from the line.

Electronic voltage controllers

A straightforward voltage/current controller can be produced using a resistor in arrangement with a diode (or arrangement of diodes). Because of the logarithmic state of diode V-I bends, the voltage over the diode changes just somewhat because of changes in current attracted or changes the info. At the point when exact voltage control and proficiency are not critical, this outline may work fine.

Criticism voltage controllers work by contrasting the genuine yield voltage with some settled reference voltage. Any distinction is enhanced and used to control the direction component so as to lessen the voltage mistake. This structures a negative input control circle; expanding the open-circle increase tends to build direction precision however decrease soundness. (Dependability is evasion of wavering, or ringing, amid step changes.) There will likewise be an exchange off amongst soundness and the speed of the reaction to changes. On the off chance that the yield voltage is too low (maybe because of information voltage lessening or load current expanding), the direction component is instructed, to a limited degree, to deliver a higher yield voltage–by dropping less of the info voltage (for straight arrangement controllers and buck exchanging controllers), or to draw include current for longer periods (help sort exchanging controllers); if the yield voltage is too high, the direction component will typically be summoned to create a lower voltage. Notwithstanding, numerous controllers have over-current assurance, so they will totally quit sourcing current (or cutoff the current somehow) if the yield current is too high, and a few controllers may likewise close down if the information voltage is outside a given range (see additionally: crowbar circuits).

Voltage controller for generators.

To control the yield of generators (as found in boats and power stations, or on oil apparatuses, nurseries and crisis control frameworks) programmed voltage controllers are utilized. This is a dynamic framework. While the fundamental guideline is the same, the framework itself is more unpredictable. A programmed voltage controller (or AVR for short) comprises of a few segments, for example, diodes, capacitors, resistors and potentiometers or even microcontrollers, all set on a circuit board. This is then mounted close to the generator and associated with a few wires to quantify and conform the generator.

How an AVR functions: in any case the AVR screens the yield voltage and controls the information voltage for the exciter of the generator. By expanding or diminishing the generator control voltage, the yield voltage of the generator increments or declines likewise. The AVR computes how much voltage must be sent to the exciter various times each second, in this way balancing out the yield voltage to a foreordained setpoint. Whenever at least two generators are controlling a similar framework (parallel operation) the AVR gets data from more generators to match all yield

Resistance

electrical resistance of

an electrical transport is a measure of the inconvenience to pass an electric

current through that channel. The inverse sum is electrical conductance, and is

the straightforwardness with which an electric current passes. Electrical

resistance grants some sensible parallels to the possibility of mechanical

pounding. The SI unit of electrical resistance is the ohm (Ω), while electrical

conductance is measured in siemens (S).

A dissent of uniform cross

portion has a resistance comparing to its resistivity and length and on the

other hand in respect to its cross-sectional zone. All materials show some

resistance, except for superconductors, which have a resistance of zero.

The resistance (R) of a

question is described as the extent of voltage transversely over it (V) to

current through it (I), while the conductance (G) is the turn around:

{\displaystyle R={V \over

I},\qquad G={I \over V}={\frac {1}{R}}} R = {V\over I}, \qquad G = {I\over V} =

\frac{1}{R}

For a wide combination of

materials and conditions, V and I are particularly relating to each other, and

in this way R and G are enduring (notwithstanding the way that they can depend

on upon various segments like temperature or strain). This proportionality is

called Ohm's law, and materials that satisfy it are called ohmic materials.

In various cases, for

instance, a diode or battery, V and I are not particularly relating. The extent

V/I is from time to time still significant, and is suggested as a "chordal

resistance" or "static resistance",[1][2] since it identifies

with the regressive grade of an agreement between the start and an I–V twist.

In various conditions, the subordinate {\displaystyle {\frac {dV}{dI}}\,\!}

\frac{dV}{dI} \,\! may be most useful; this is known as the "differential

resistance".

Presentation

The pressure driven

similarity thinks about electric ebb and flow moving through circuits to water

moving through funnels. At the point when a pipe (left) is loaded with hair

(right), it takes a bigger weight to accomplish a similar stream of water.

Pushing electric ebb and flow through a vast resistance resemble pushing water

through a pipe stopped up with hair: It requires a bigger push (electromotive

compel) to drive a similar stream (electric momentum).

In the pressure driven

similarity, ebb and flow coursing through a wire (or resistor) resemble water

moving through a pipe, and the voltage drop over the wire resemble the weight

drop that pushes water through the pipe. Conductance is corresponding to how much

stream happens for a given weight, and resistance is relative to how much

weight is required to accomplish a given stream. (Conductance and resistance

are reciprocals.)

The voltage drop (i.e.,

contrast between voltages on one side of the resistor and the other), not the

voltage itself, gives the main impetus pushing current through a resistor. In

power through pressure, it is comparable: The weight contrast between two sides

of a pipe, not the weight itself, decides the move through it. For instance, there

might be an expansive water weight over the pipe, which tries to push dilute

through the pipe. Be that as it may, there might be a similarly huge water

weight underneath the pipe, which tries to push water go down through the pipe.

On the off chance that these weights are equivalent, no water streams. (In the

picture at right, the water weight beneath the pipe is zero.)

The resistance and

conductance of a wire, resistor, or other component is for the most part

controlled by two properties:

geometry (shape), and

material

Geometry is essential

since it is more hard to push water through a long, contract pipe than a wide,

short pipe. Similarly, a long, thin copper wire has higher resistance (bring

down conductance) than a short, thick copper wire.

Materials are vital too. A

pipe loaded with hair limits the stream of water more than a perfect pipe of a

similar shape and size. Likewise, electrons can stream unreservedly and

effectively through a copper wire, however can't stream as effortlessly through

a steel wire of a similar shape and size, and they basically can't stream at

all through an encasing like elastic, paying little heed to its shape. The

distinction between, copper, steel, and elastic is identified with their

minuscule structure and electron arrangement, and is measured by a property

called resistivity.

Notwithstanding geometry

and material, there are different components that impact resistance and

conductance, for example, temperature; see beneath.

onductors and resistors

A 6.5 Mω resistor, as

distinguished by its electronic shading code (blue–green–black-yellow). An

ohmmeter could be utilized to confirm this esteem.

Substances in which power

can stream are called conductors. A bit of directing material of a specific

resistance implied for use in a circuit is known as a resistor. Conveyors are

made of high-conductivity materials, for example, metals, specifically copper

and aluminum. Resistors, then again, are made of a wide assortment of materials

relying upon elements, for example, the fancied resistance, measure of vitality

that it needs to scatter, accuracy, and expenses.

Ohm's law

The present voltage

attributes of four gadgets: Two resistors, a diode, and a battery. The level

hub is voltage drop, the vertical pivot is present. Ohm's law is fulfilled when

the diagram is a straight line through the root. In this way, the two resistors

are ohmic, however the diode and battery are most certainly not.

The present voltage

attributes of four gadgets: Two resistors, a diode, and a battery. The level

hub is voltage drop, the vertical pivot is present. Ohm's law is fulfilled when

the diagram is a straight line through the root. In this way, the two resistors

are ohmic, however the diode and battery are most certainly not.

Fundamental article: Ohm's

law

Ohm's law is an

observational law relating the voltage V over a component to the current

Ithrough it:

(I is straightforwardly

corresponding to V). This law is not generally valid: For instance, it is false

for diodes, batteries, and different gadgets whose conductance is not

consistent. Be that as it may, it is consistent with a decent guess for wires

and resistors (expecting that different conditions, including temperature, are

held steady). Materials or articles where Ohm's law is genuine are called

ohmic, while objects that don't comply with Ohm's law are non-ohmic.

Transistor

1015 Transistor (IC) Datasheet. Cross Reference Search. A1015 Equivalent

Sort Designator: A1015

Material of transistor: Si

Extremity: PNP

Greatest authority control scattering (Pc), W: 0.2

Most extreme authority base voltage |Ucb|, V: 50

Most extreme authority emitter voltage |Uce|, V: 50

Most extreme emitter-base voltage |Ueb|, V: 5

Most extreme authority current |Ic max|, A: 0.15

Maksimalna temperatura (Tj), °C: 125

Move recurrence (ft), MHz: 80

Gatherer capacitance (Cc), pF:

Forward current exchange proportion (hFE), min: 130

Commotion Figure, dB: -

Bundle of A1015 transistor: SOT23

2SA1015 TOSHIBA Transistor Silicon PNP Epitaxial Type (PCT handle) 2SA1015 Audio Frequency General Purpose Amplifier Applications Unit: mm Driver Stage Amplifier Applications � High voltage and high ebb and flow: VCEO = - 50 V (min), I = - 150 mA (max) C � Excellent h linearity: h = 80 (typ.) at V = - 6 V, I = - 150 mA FE (2) CE C : hFE (IC = - 0.1 mA)/hFE (IC = - 2 mA) = 0.95 (typ.)

KSA1015 LOW FREQUENCY AMPLIFIER � Collector-Base Voltage : VCBO= - 50V � Complement to KSC1815 TO-92 1. Emitter 2. Authority 3. Base PNP Epitaxial Silicon Transistor Absolute Maximum Ratings Ta=25�C unless generally noted Symbol Parameter Ratings Units VCBO Collector-Base Voltage - 50 V VCEO Collector-Emitter Voltage - 50 V VEBO Emitter-Base Voltage - 5 V IC Collector Current - 150 mA

Sort Designator: A1015

Material of transistor: Si

Extremity: PNP

Greatest authority control scattering (Pc), W: 0.2

Most extreme authority base voltage |Ucb|, V: 50

Most extreme authority emitter voltage |Uce|, V: 50

Most extreme emitter-base voltage |Ueb|, V: 5

Most extreme authority current |Ic max|, A: 0.15

Maksimalna temperatura (Tj), °C: 125

Move recurrence (ft), MHz: 80

Gatherer capacitance (Cc), pF:

Forward current exchange proportion (hFE), min: 130

Commotion Figure, dB: -

Bundle of A1015 transistor: SOT23

2SA1015 TOSHIBA Transistor Silicon PNP Epitaxial Type (PCT handle) 2SA1015 Audio Frequency General Purpose Amplifier Applications Unit: mm Driver Stage Amplifier Applications � High voltage and high ebb and flow: VCEO = - 50 V (min), I = - 150 mA (max) C � Excellent h linearity: h = 80 (typ.) at V = - 6 V, I = - 150 mA FE (2) CE C : hFE (IC = - 0.1 mA)/hFE (IC = - 2 mA) = 0.95 (typ.)

KSA1015 LOW FREQUENCY AMPLIFIER � Collector-Base Voltage : VCBO= - 50V � Complement to KSC1815 TO-92 1. Emitter 2. Authority 3. Base PNP Epitaxial Silicon Transistor Absolute Maximum Ratings Ta=25�C unless generally noted Symbol Parameter Ratings Units VCBO Collector-Base Voltage - 50 V VCEO Collector-Emitter Voltage - 50 V VEBO Emitter-Base Voltage - 5 V IC Collector Current - 150 mA

Motor Cotroler

An electric engine controller can be ordered by the sort of engine it is to drive, for example, changeless magnet, servo, arrangement, independently energized, and rotating current.

An engine controller is associated with a power source, for example, a battery pack or power supply, and control hardware as simple or advanced information signals.

Engine starters

See likewise: Motor delicate starter

A little engine can be begun by just connecting it to an electrical repository or by utilizing a switch or electrical switch. A bigger engine requires a particular exchanging unit called an engine starter or engine contactor. Whenever stimulated, a direct on line (DOL) starter promptly interfaces the engine terminals straightforwardly to the power supply. Lessened voltage, star-delta or delicate starters associate the engine to the power supply through a voltage diminishment gadget and expands the connected voltage bit by bit or in steps.[2][3][4] In littler sizes an engine starter is a physically worked switch; bigger engines, or those requiring remote or programmed control, utilize attractive contactors. Large engines running on medium voltage control supplies (a large number of volts) may utilize control circuit breakers as exchanging components.

A direct on line (DOL) or over the line starter applies the full line voltage to the engine terminals, the starters or work space areas, can more often than not be found on an ELO drawing. This is the easiest kind of engine starter. A DOL engine starter likewise contains assurance gadgets, and sometimes, condition checking. Littler sizes of direct on-line starters are physically worked; bigger sizes utilize an electromechanical contactor (hand-off) to switch the engine circuit. Strong state coordinate on line starters additionally exist.

A direct on line starter can be utilized if the high inrush current of the engine does not bring about over the top voltage drop in the supply circuit. The greatest size of an engine permitted on a direct on line starter might be restricted by the supply utility therefore. For instance, an utility may require provincial clients to utilize lessened voltage starters for engines bigger than 10 kW.[5]

DOL beginning is here and there used to begin little water pumps, compressors, fans and transport lines. On account of a nonconcurrent engine, for example, the 3-stage squirrel-confine engine, the engine will draw a high beginning current until it has keep running up to full speed. This beginning current is regularly 6-7 times more prominent than the full load current. To decrease the inrush present, bigger engines will have diminished voltage starters or variable speed drives keeping in mind the end goal to minimize voltage plunges to the power supply.

A turning around starter can interface the engine for pivot in either bearing. Such a starter contains two DOL circuits—one for clockwise operation and the other for counter-clockwise operation, with mechanical and electrical interlocks to avoid synchronous closure.[5] For three stage engines, this is accomplished by swapping the wires interfacing any two stages. Single stage AC engines and direct-current engines require extra gadgets for switching revolution.

Over-burden transfers

A starter will contain defensive gadgets for the engine. At least this would incorporate a warm over-burden hand-off. The warm over-burden is intended to open the beginning circuit and subsequently slice the ability to the engine in case of the engine drawing a lot of current from the supply for an expanded time. The over-burden hand-off has a regularly shut contact which opens because of warmth created by intemperate current coursing through the circuit. Warm over-burdens have a little warming gadget that increments in temperature as the engine running current increments.

There are two sorts of warm over-burden transfer. In one write, a bi-metallic strip found near a warmer redirects as the radiator temperature ascends until it mechanically causes the gadget to excursion and open the circuit, slicing energy to the engine should it get to be over-burden. A warm over-burden will oblige the brief high beginning current of an engine while precisely shielding it from a running current over-burden. The warmer loop and the activity of the bi-metallic strip present a period defer that manages the engine time to begin and subside into typical running current without the warm over-burden stumbling. Warm over-burdens can be physically or naturally resettable relying upon their application and have an agent that permits them to be precisely set to the engine run current.

A second sort of warm over-burden hand-off utilizations an eutectic combination, similar to a patch, to hold a spring-stacked contact. At the point when an excess of current goes through the warming component for a really long time a period, the combination dissolves and the spring discharges the contact, opening the control circuit and closing down the engine. Since eutectic amalgam components are not movable, they are impervious to easygoing altering but rather require changing the warmer loop component to coordinate the engine appraised current.[5]

Electronic computerized over-burden transfers containing a chip may likewise be utilized, particularly for high-esteem engines. These gadgets display the warming of the engine windings by checking the engine current. They can likewise incorporate metering and correspondence capacities.

An engine controller is associated with a power source, for example, a battery pack or power supply, and control hardware as simple or advanced information signals.

Engine starters

See likewise: Motor delicate starter

A little engine can be begun by just connecting it to an electrical repository or by utilizing a switch or electrical switch. A bigger engine requires a particular exchanging unit called an engine starter or engine contactor. Whenever stimulated, a direct on line (DOL) starter promptly interfaces the engine terminals straightforwardly to the power supply. Lessened voltage, star-delta or delicate starters associate the engine to the power supply through a voltage diminishment gadget and expands the connected voltage bit by bit or in steps.[2][3][4] In littler sizes an engine starter is a physically worked switch; bigger engines, or those requiring remote or programmed control, utilize attractive contactors. Large engines running on medium voltage control supplies (a large number of volts) may utilize control circuit breakers as exchanging components.

A direct on line (DOL) or over the line starter applies the full line voltage to the engine terminals, the starters or work space areas, can more often than not be found on an ELO drawing. This is the easiest kind of engine starter. A DOL engine starter likewise contains assurance gadgets, and sometimes, condition checking. Littler sizes of direct on-line starters are physically worked; bigger sizes utilize an electromechanical contactor (hand-off) to switch the engine circuit. Strong state coordinate on line starters additionally exist.

A direct on line starter can be utilized if the high inrush current of the engine does not bring about over the top voltage drop in the supply circuit. The greatest size of an engine permitted on a direct on line starter might be restricted by the supply utility therefore. For instance, an utility may require provincial clients to utilize lessened voltage starters for engines bigger than 10 kW.[5]

DOL beginning is here and there used to begin little water pumps, compressors, fans and transport lines. On account of a nonconcurrent engine, for example, the 3-stage squirrel-confine engine, the engine will draw a high beginning current until it has keep running up to full speed. This beginning current is regularly 6-7 times more prominent than the full load current. To decrease the inrush present, bigger engines will have diminished voltage starters or variable speed drives keeping in mind the end goal to minimize voltage plunges to the power supply.

A turning around starter can interface the engine for pivot in either bearing. Such a starter contains two DOL circuits—one for clockwise operation and the other for counter-clockwise operation, with mechanical and electrical interlocks to avoid synchronous closure.[5] For three stage engines, this is accomplished by swapping the wires interfacing any two stages. Single stage AC engines and direct-current engines require extra gadgets for switching revolution.

Over-burden transfers

A starter will contain defensive gadgets for the engine. At least this would incorporate a warm over-burden hand-off. The warm over-burden is intended to open the beginning circuit and subsequently slice the ability to the engine in case of the engine drawing a lot of current from the supply for an expanded time. The over-burden hand-off has a regularly shut contact which opens because of warmth created by intemperate current coursing through the circuit. Warm over-burdens have a little warming gadget that increments in temperature as the engine running current increments.

There are two sorts of warm over-burden transfer. In one write, a bi-metallic strip found near a warmer redirects as the radiator temperature ascends until it mechanically causes the gadget to excursion and open the circuit, slicing energy to the engine should it get to be over-burden. A warm over-burden will oblige the brief high beginning current of an engine while precisely shielding it from a running current over-burden. The warmer loop and the activity of the bi-metallic strip present a period defer that manages the engine time to begin and subside into typical running current without the warm over-burden stumbling. Warm over-burdens can be physically or naturally resettable relying upon their application and have an agent that permits them to be precisely set to the engine run current.

A second sort of warm over-burden hand-off utilizations an eutectic combination, similar to a patch, to hold a spring-stacked contact. At the point when an excess of current goes through the warming component for a really long time a period, the combination dissolves and the spring discharges the contact, opening the control circuit and closing down the engine. Since eutectic amalgam components are not movable, they are impervious to easygoing altering but rather require changing the warmer loop component to coordinate the engine appraised current.[5]

Electronic computerized over-burden transfers containing a chip may likewise be utilized, particularly for high-esteem engines. These gadgets display the warming of the engine windings by checking the engine current. They can likewise incorporate metering and correspondence capacities.

Thursday, November 3, 2016

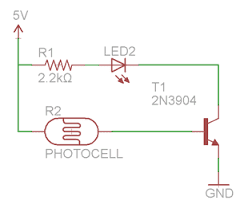

Dark Circuit LED

In this venture, we will go over how to manufacture a dim initiated light circuit.

This is a circuit whose light will turn on once it is presented to murkiness. So it's a light that will go ahead when it gets dull, for example, at evening.

This is amazingly valuable for individuals who may live in a house that have vision issues and need the lights to consequently turn on when it gets dull. It's likewise extremely helpful for elderly individuals who live in a home who may experience issues strolling to turn on lights when it gets to be dull.

In our circuit, we will turn on a light when the level of light achieves a specific level of obscurity. Along these lines, the place where we put this circuit will dependably be lit up, either by the common light of the day or by the light of this circuit turning on when it gets to be dim.

Segments Needed

Photoresistor

330KΩ Resistor

2N3904 NPN Transistor

Driven

2 AA batteries or DC Power Supply

What we will use for this circuit is a photoresistor. Photoresistors are likewise called light-subordinate resistors (LDRs). This can be gotten at digikey at the accompanying connection: Tayda Electronics-Photoresistor. In the event that you don't have a photoresistor, quite recently make a point to utilize one that has a dull resistance of at least 2mω and a light resistance of around 20-30KΩ.

A photoresistor is a resistor whose resistance changes as indicated by the measure of light that it is presented to. At the point when presented to aggregate haziness, the photoresistor's resistance is high. This is called its appraised dim resistance. For instance, for our situation we are utilizing a 2MΩ photoresistor. This implies when presented to aggregate murkiness, its resistance will be around 2MΩ. As the photoresistor is presented to expanding measures of light, its resistance starts to drop fundamentally. There is another rating on the datasheet named cell resistance @ illuminance. This is the resistance that the photoresistor will drop to when presented to brilliant light, regularly 10 lux. This is additionally called the light resistance (since it is the resistance the photoresistor has when presented to brilliant light). For our photoresistor, specifically the phone resistance @ illuminance is 20-30kω. This implies the resistance of the photoresistor will drop to 20-30KΩ when presented to 10 lux level of light.

So a photoresistor is fundamentally a gadget that radiates high resistance at dim light levels and low resistance at high light levels. Being that it does this, it can go about as a sensor for light, or a photosensor.

With the photoresistor going about as the light sensor, the other critical part is the 2N3904 transistor. The transistor in this circuit will go about as an intensifier, increasing current so that adequate current is delivered to light the light.

Any sort of LED can be utilized for this circuit.

The power we will use for this circuit is a 3 volts, which can be acquired from either 2 "AA" batteries in arrangement or from a DC control supply set to this voltage.

Along these lines, for this circuit, 3 volts is driving the circuit. This 3 volts is in parallel to a 100KΩ resistor and the photoresistor. Amidst these 2 segments is associated the base of the NPN 2N3904 transistor.

This is the means by which the circuit works:

At the point when presented to brilliant light, the photoresistor's resistance is low. It drops to around 20-30KΩ. Current goes through the 100KΩ resistor and afterward has 2 ways it can either experience the base of the transistor or experience the photoresistor. The base of the resistor to the authority has a resistance of around 400KΩ. Current dependably takes the easy way out. At the point when the photoresistor is presented to brilliant light, its resistance is around 20-30KΩ, which is altogether not exactly the 400KΩ of resistance the base of the transistor has. In this manner, the greater part of the present will experience the photoresistor and next to no will go to the base of the transistor. So the base of the transistor is circumvent. Accordingly, the transistor does not get enough present to turn on and control on the LED. Along these lines, the LED is off when there is a considerable measure of light in the environment.

Nonetheless, when it starts to get dull, the photoresistor's resistance turns out to be high. Its resistance goes up to more than 2MΩ of resistance. This makes a high-resistance way. Being that 2MΩ is altogether more prominent than the 400KΩ of resistance that the base of the transistor offers, a large portion of the present will experience the base of the transistor. This implies current does not experience the photoresistor when it is dim, because of this high resistance. Rather present experiences the 100KΩ resistor and through the base of the transistor. The transistor gets enough present to control on and turn on the LED associated with the authority terminal.

So this is the manner by which a dull actuated light circuit can work.

Once more, as usual, varieties of this circuit should be possible. Rather than utilizing am LED, we can utilize some other kind of lighting installation, for example, a light. You might need to utilize a brilliant LED. Then again you can utilize some other different lighting source. You might need to utilize numerous lights, so you can put diverse lights in parallel in each other. All that would be required is a conformity in the voltage and current of the circuit. Redo the circuit as indicated by your requirements and inclinations.

This is a circuit whose light will turn on once it is presented to murkiness. So it's a light that will go ahead when it gets dull, for example, at evening.

This is amazingly valuable for individuals who may live in a house that have vision issues and need the lights to consequently turn on when it gets dull. It's likewise extremely helpful for elderly individuals who live in a home who may experience issues strolling to turn on lights when it gets to be dull.

In our circuit, we will turn on a light when the level of light achieves a specific level of obscurity. Along these lines, the place where we put this circuit will dependably be lit up, either by the common light of the day or by the light of this circuit turning on when it gets to be dim.

Segments Needed

Photoresistor

330KΩ Resistor

2N3904 NPN Transistor

Driven

2 AA batteries or DC Power Supply

What we will use for this circuit is a photoresistor. Photoresistors are likewise called light-subordinate resistors (LDRs). This can be gotten at digikey at the accompanying connection: Tayda Electronics-Photoresistor. In the event that you don't have a photoresistor, quite recently make a point to utilize one that has a dull resistance of at least 2mω and a light resistance of around 20-30KΩ.

A photoresistor is a resistor whose resistance changes as indicated by the measure of light that it is presented to. At the point when presented to aggregate haziness, the photoresistor's resistance is high. This is called its appraised dim resistance. For instance, for our situation we are utilizing a 2MΩ photoresistor. This implies when presented to aggregate murkiness, its resistance will be around 2MΩ. As the photoresistor is presented to expanding measures of light, its resistance starts to drop fundamentally. There is another rating on the datasheet named cell resistance @ illuminance. This is the resistance that the photoresistor will drop to when presented to brilliant light, regularly 10 lux. This is additionally called the light resistance (since it is the resistance the photoresistor has when presented to brilliant light). For our photoresistor, specifically the phone resistance @ illuminance is 20-30kω. This implies the resistance of the photoresistor will drop to 20-30KΩ when presented to 10 lux level of light.

So a photoresistor is fundamentally a gadget that radiates high resistance at dim light levels and low resistance at high light levels. Being that it does this, it can go about as a sensor for light, or a photosensor.

With the photoresistor going about as the light sensor, the other critical part is the 2N3904 transistor. The transistor in this circuit will go about as an intensifier, increasing current so that adequate current is delivered to light the light.

Any sort of LED can be utilized for this circuit.

The power we will use for this circuit is a 3 volts, which can be acquired from either 2 "AA" batteries in arrangement or from a DC control supply set to this voltage.

Along these lines, for this circuit, 3 volts is driving the circuit. This 3 volts is in parallel to a 100KΩ resistor and the photoresistor. Amidst these 2 segments is associated the base of the NPN 2N3904 transistor.

This is the means by which the circuit works:

At the point when presented to brilliant light, the photoresistor's resistance is low. It drops to around 20-30KΩ. Current goes through the 100KΩ resistor and afterward has 2 ways it can either experience the base of the transistor or experience the photoresistor. The base of the resistor to the authority has a resistance of around 400KΩ. Current dependably takes the easy way out. At the point when the photoresistor is presented to brilliant light, its resistance is around 20-30KΩ, which is altogether not exactly the 400KΩ of resistance the base of the transistor has. In this manner, the greater part of the present will experience the photoresistor and next to no will go to the base of the transistor. So the base of the transistor is circumvent. Accordingly, the transistor does not get enough present to turn on and control on the LED. Along these lines, the LED is off when there is a considerable measure of light in the environment.

Nonetheless, when it starts to get dull, the photoresistor's resistance turns out to be high. Its resistance goes up to more than 2MΩ of resistance. This makes a high-resistance way. Being that 2MΩ is altogether more prominent than the 400KΩ of resistance that the base of the transistor offers, a large portion of the present will experience the base of the transistor. This implies current does not experience the photoresistor when it is dim, because of this high resistance. Rather present experiences the 100KΩ resistor and through the base of the transistor. The transistor gets enough present to control on and turn on the LED associated with the authority terminal.

So this is the manner by which a dull actuated light circuit can work.

Once more, as usual, varieties of this circuit should be possible. Rather than utilizing am LED, we can utilize some other kind of lighting installation, for example, a light. You might need to utilize a brilliant LED. Then again you can utilize some other different lighting source. You might need to utilize numerous lights, so you can put diverse lights in parallel in each other. All that would be required is a conformity in the voltage and current of the circuit. Redo the circuit as indicated by your requirements and inclinations.

Electric Gun

Airsoft is a well known battle reproduction amusement in

which players are wiped out when hit by pellets discharged from sensible

looking weapons, called an airsoft firearm. While these weapons may look

savage, they are innocuous when utilized with appropriate frill, wellbeing

apparatus and sound judgment, permitting individuals to take part in taunt

battle with each other, either separately or on groups.

Whether somebody is simply wandering into this pastime, or

hoping to add another airsoft firearm to his or her accumulation, it's

imperative to have a fundamental comprehension of the sorts of airsoft weapons

accessible. All airsoft weapons include moving a little plastic BB or pellet

out of the barrel at paces going from 150 - 600 feet for each second (fps). How

they finish this accomplishment depends on the kind of firearm. There are three

sorts of airsoft weapons, each with uniquely extraordinary attributes that

improve them suited to specific circumstances and clients. They are

electric-controlled firearms, gas-fueled weapons, and spring-fueled firearms

History of Airsoft

Airsoft was outlined in Japan amid the mid 1970's. It was

initially designed as a reaction to an across the nation prohibition on regular

citizens owning guns. It gave a reasonable other option to shooting genuine

firearms and in the 1980s the amusement rapidly spread through Asia and into

the U.S. From that point forward, airsoft weapons have been a well known other

option to BB firearms and paintball weapons, because of their less harming

nature. Airsoft wearing is additionally ordinarily less expensive than

paintball.

An Overview of Electric, Gas, and Spring Airsoft Guns

The three sorts of airsoft weapons all discharge plastic

pellets out of their barrels, yet the innovation behind every kind of firearm

is entirely extraordinary. While it's not important to have a full information

of how each airsoft firearm functions, it is critical to have general learning

of the distinctive sorts of weapons.

Spring Airsoft Guns

Spring firearms are the most fundamental kind of airsoft

weapon available. As the name infers, spring airsoft firearms utilize a spring

to flame a plastic pellet out of their barrels. They take a shot at mechanical

power, implying that the client must cockerel the weapon after each round is

discharged, much like a shotgun or jolt activity rifle. Spring-fueled firearms

are ordinarily observed as section level airsoft weapons, in spite of the fact

that spring-controlled expert sharpshooter rifles can be capable upper-level

fun.

Gas Airsoft Guns

A few clients choose controlled airsoft weapons.

Gas-controlled airsoft firearms utilize a wide range of sorts of compacted gas

to flame the BBs. They are commonly observed as middle of the road weapons and

are extremely valuable for outside sport shooting. They regularly shoot BBs at

higher speeds than spring-controlled airsoft firearms and are additionally

self-loader. Certain models are additionally completely programmed, in spite of

the fact that it's critical to check the particular model of the weapon to

figure out which discharging strategy is accessible. Gas-fueled airsoft

firearms mostly utilize propane as propellent (usually alluded to as

"green gas"), CO2 gas airsoft rifles are auto and customizable to

self-loader, and can shoot different BBs on the double without positioning or

reloading. CO2 gas weapons for the most part discharge at a higher FPS and

shoot a more grounded shot than their green gas partners. Different sorts

incorporate nitrogen and HFC134a refrigerant.

Electric Airsoft Guns

Like spring-controlled airsoft firearms, electric airsoft

weapons additionally utilize springs, however they do as such without the need

to physically chicken the weapon. They more often than exclude a rechargeable

battery and battery charger. Electric weapons are self-loader, and numerous

have completely programmed, or full metal, capacities. Electric weapons are the

most famous style of airsoft firearm in group and class play. An airsoft rifle,

ambush rifles and other electric fueled airsoft items are for airsoft devotees

who need to pack themselves out for military recreation works out. They're

valued by and large mirrors this.

Gun Versus Rifle

Despite which kind of firearm a player picks, he or she

likewise needs to settle on a gun or a rifle. This is absolutely valid for gas

and spring weapons, however it is less valid for electric firearms. Since

electric firearms have the unmistakable reward of offering completely

programmed, full metal terminating, they have to hold a vast quantities of

rounds. Guns, by ethicalness of their size, can't hold numerous rounds; hence,

there are couple of electric guns accessible.

At the point when picking between a gun and a rifle, there

are four things to consider: value, limit, size, and power. Rifles have the

upside of being all the more capable, more exact, and ready to hold a much

bigger number of rounds. Then again, they are more costly, heavier, and harder

to move around other people. Before picking between an electric, gas, or

spring-fueled firearm, it's essential to know about the focal points and

disservices of guns and rifles.

Simple Circuit with a Battery

1

Assemble the essential materials. To assemble a basic circuit, you will

require a power source, two protected wires, a light, and a light holder. A

power source can be any sort of battery or battery pack. Whatever is left of

the materials can be found at your neighborhood handyman shop.

While picking a light, remember the measure of force your battery radiates.

To disentangle the wire connection handle, utilize a battery snap with

wires pre-appended and a nine volt battery or battery pack.

Strip the finishes of the protected wires. All together for your circuit to

work legitimately, the wires should be completely uncovered so you should strip

the closures. Utilizing wire strippers, expel around a crawl of the protection

from the closures of every wire.

On the off chance that you don't have wire strippers, you can precisely

utilize scissors to remove the protection.

Be mindful so as not to carve completely through the wire.

3

Introduce batteries into battery pack. Contingent upon the kind of

batteries you are utilizing, you might have the capacity to avoid this

progression. On the off chance that you are utilizing different batteries, you

will require a power pack to hold the batteries. Push every battery in by the

side taking consideration to put the positive and negative closures in the

right introduction.

4

Join your wires to the battery pack. The wires will lead your electric

current from the batteries to the light. The most effortless approach to

connect the wires is to utilize electrical tape. Join the end of one wire to

the other side of the battery, ensuring that the wire keeps up contact with the

metal of the battery. Rehash with the other wire on the opposite side of the

battery.

On the other hand, in the event that you are utilizing a battery snap, snap

the end onto the end of a nine volt battery or the battery pack.

Utilize alert while building your circuit. Albeit impossible, it is

conceivable to get a little stun in the event that you touch the wire

specifically while connected to the battery. You can keep away from this by

just touching the protected part of the wire or evacuating the batteries until

you introduce the light.

Secure the flip side of the wire to the metal screw of the knob holder.

Take the uncovered metal end of every wire and twist it into a U-shape.[3]

Loosen every screw on the light holder sufficiently only to slip the U-state of

the wire around the screw. Every wire will be joined to its own screw. Fix the

screw, guaranteeing that the metal of the wires stay in contact with the screw.

Test your circuit. Screw the light into its holder until it is tight. On

the off chance that your circuit is snared appropriately, the globule ought to

illuminate when completely screwed into its attachment.

Electrical shock

|

| electrical shoch |

1. Isolate the Person

From Current's Source

To kill control:

Unplug a machine if

fitting is undamaged or close off power by means of electrical switch,

intertwine box, or outside switch.

On the off chance that

you can't kill control:

Remain on something dry

and non-conductive, for example, dry daily papers, phone directory, or wooden

board.

Attempt to isolate the

individual from current utilizing non-conductive question, for example, wooden

or plastic floor brush handle, seat, or elastic doormat.

On the off chance that

high voltage lines are included:

The neighborhood control

organization must close them off.

Try not to attempt to

isolate the individual from current on the off chance that you feel a shivering

sensation in your legs and lower body. Jump on one foot to a protected place

where you can sit tight for lines to be disengaged.

In the event that an

electrical cable falls on an auto, educate the travelers to remain inside

unless blast or fire undermines.

2. Perform mouth to

mouth, if Necessary

When you can securely

touch the individual, perform mouth to mouth if the individual is not breathing

or does not have a heartbeat.

For a tyke, begin CPR for

kids

For a grown-up, begin

grown-up CPR.

3. Check for Other

Injuries

On the off chance that

the individual is dying, apply weight and hoist the injury if it's in an arm or

leg.

There might be a crack if

the stun brought on the individual to fall.

For smolders, see Burn

Treatment.

Limit switch

Using limit

switches to control behavior

Limit switches are often

used to control mechanisms on robots. While limit switches are simple to use,

they only can sense a single position of a moving part. This makes them ideal

for ensuring that movement doesn't exceed some limit but not so good at controlling

the speed of the movement as it approaches the limit. For example, a rotational

shoulder joint on a robot arm would best be controlled using a potentiometer or

an absolute encoder, the limit switch could make sure that if the potentiometer

ever failed, the limit switch would stop the robot from going to far and

causing damage.

What values

are provided by the limit switch

Limit switches can have

"normally opened" or "normally closed" outputs. The usual

way of wiring the switch is between a digital input signal connection and

ground. The digital input has pull-up resistors that will make the input be

high (1 value) when the switch is open, but when the switch closes the value

goes to 0 since the input is now connected to ground. The switch shown here has

both normally open and normally closed outputs.

It's possible that a

limit switch might close then open again as a mechanism moves past the switch.

If the closure is fast enough the program might not notice that the switch

closed. An alternative method of catching the switch closing is use a Counter

object. Since counters are implemented in hardware, it will be able to capture

the closing of the fastest switches and increment it's count. Then the program

can simply notice that the count has increased and take whatever steps are

needed to do the operation.

Above is a subsystem that

uses a counter to watch the limit switch and wait for the value to change. When

it does, the counter will increment and that can be watched in a command.

How to make LED circuit

Your LEDs ought to be

situated on the board as found in the graph beneath. Every line ought to have

four LEDs associated together in arrangement from + to - to + to - et cetera.

Allude to the photograph

underneath for the following stride. As you achieve the end of every column,

leave the outside LED leg long. Twist it over to reach crosswise over to the

LED alongside it. Zoom in on the photograph to perceive how the LED legs on the

outside lines are bound together along the edges. On the left side will be the

positive lead. On the right side is the negative lead.

In the photograph beneath, the voltage is just set to 10 volts and the couple of LEDs on the board are now putting out a decent measure of light. These are less expensive LEDs, so the light yield is a tiny bit blue tinted. Yet, who cares, at that cost.

In the photograph beneath, the voltage is just set to 10 volts and the couple of LEDs on the board are now putting out a decent measure of light. These are less expensive LEDs, so the light yield is a tiny bit blue tinted. Yet, who cares, at that cost.

Continue welding and

adding columns to your LED light until the perfboard is full. The one in our

case has 8 lines of 4 LEDs for an aggregate of 32 LEDs.

Test your new DIY LED

globule again on the seat to ensure all the weld associations are great. In the

photograph, you can see that the LED light is sufficiently radiating vitality

to illuminate even the work surface beneath the LEDs. That is a great deal of

light.

Think about your new natively constructed LED light to retail forms

demonstrated as follows. They greatest contrast is cost. You can make your own

particular LED lights at a small amount of the cost as the retail forms and

they can be custom fitted to your own needs. Another favorable position is if a

LED bombs on your natively constructed

How to make (construct) ATS (Automatic Transfer Switch) ?

Re: How to

make (construct) ATS (Automatic Transfer Switch) ?

The

wellbeing insurances are that you should ensure that there is no plausibility

of the generator or the mains being associated together. For high current

cicuits when a solitary changeover transfer can't be utilized, say more than

30A. At that point a couple of contactors must be utilized, stand out at once

being chosen. To beat the far-fetched issue of one of the contactors having its

contacts welded together, i.e. at the point when the other contactor is

empowered, the first is still stuck in, the contactors are provided as a

mechanically interlocked combine, so it is physically difficult to have both

chosen without a moment's delay. Additionally if the mains are being dealt with

so you are running on the generator you would prefer not to bolster mains

"in reverse" down the mains wire to shock any of the laborers. With

programmed running you should have some kind of sign/cautions so the condition

of the oil, fuel, motor temperature... can be seen on the grounds that you may

keep running on the generator so you look at these without breaking your supply

(cos' the mains is off!!)

Honest

You have to

consider that is not a last item, that is increasingly a proof of idea

important to gives us a thought of what the last framework resembles.

|

| Automatic transfer switch |

Just on the

off chance that we may begin setting up a shopping list:

2 24V/16A-25A Main contactors

3 230Vac/24Vac transformers

4 1 amp rectifier connect

1 24V hand-off

1 temp hand-off

1 DPDT switch

12 terminals piece

1 box

A few

capacitors/resistors/wires (fuses= critical points of interest missing on the

above outline )

Work is

likewise extremely hard to evaluate, normally such a DIY venture will be for

nothing (on the off chance that you have enough time to spend for), or you may

wind up paying somebody for an entire day of work.

how to use contactor

Three-stage,

480 volt AC control comes into the three regularly open contacts at the highest

point of the contactor by means of screw terminals marked "L1,"

"L2," and "L3" (The "L2" terminal is holed up

behind a square-molded "snubber" circuit associated over the

contactor's loop terminals). Energy to the engine leaves the over-burden

radiator get together at the base of this gadget through screw terminals marked

"T1," "T2," and "T3."

A white

pushbutton situated between the "T1" and "T2" line

radiators serves as an approach to physically re-set the ordinarily shut change

contact back to its ordinary state subsequent to having been stumbled by

exorbitant warmer temperature. Wire associations with the "over-burden"

switch contact might be seen at the lower-right of the photo, almost a mark

perusing "NC" (ordinarily shut). On this specific over-burden unit, a

little "window" with the name "Stumbled" demonstrates a

stumbled condition by method for a shaded banner. In this photo, there is no

"stumbled" condition, and the pointer seems clear.

As a reference, radiator components might be utilized as a rough current shunt resistor for figuring out if or not an engine is drawing current when the contactor is shut. There might be times when you're taking a shot at an engine control circuit, where the contactor is situated far from the engine itself. How would you know whether the engine is expending power when the contactor loop is stimulated and the armature has been pulled in? In the event that the engine's windings are scorched open, you could send voltage to the engine through the contactor contacts, yet at the same time have zero current, and accordingly no movement from the engine shaft. On the off chance that a clasp on ammeter isn't accessible to quantify line current, you can take your multimeter and measure millivoltage over every warmer component: if the current is zero, the voltage over the radiator will be zero (unless the radiator component itself is open, in which case the voltage crosswise over it will be extensive); if there is present heading off to the engine through that period of the contactor, you will read an unequivocal millivoltage over that warmer:

Subscribe to:

Posts (Atom)